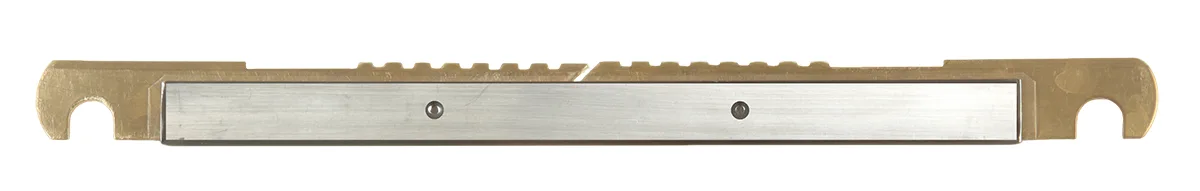

The ideal solution for projectile loom warp stop bars is Changxin Textile Equipment's Heavy-Duty Copper Warp Stop Bar. Made entirely of high-quality copper and stainless steel, it excels due to its unique shape, smooth surface, excellent straightness, high elasticity, minimal deformation, and corrosion resistance. Its structure is specifically designed for the high-speed, precision weaving characteristics of projectile looms, precisely matching operational requirements and providing stable and reliable warp break detection support for high-end fabric production.

The optimized material and structure give this Quality Heavy-Duty Copper Warp Stop Bar significant advantages.

The copper core provides excellent elasticity, with a springback rate of 94%. This allows for rapid response to changes in warp tension during high-speed weft insertion (up to 1000 rpm) on projectile looms, effectively cushioning projectile impact. Testing has shown a 16% reduction in warp breakage due to rigid impact. The special design, designed specifically for the projectile loom's weft insertion path, perfectly aligns with the warp stop frame mounting slot, ensuring smooth operation within a linearity tolerance of 0.5mm/m. The smooth surface reduces warp resistance to 0.09N, minimizing damage to fine yarn counts. It is particularly suitable for the production of high-end combed cotton, silk, and other fabrics.

The stainless steel outer layer enhances corrosion resistance. Under the high-frequency vibration of the projectile loom and the fluctuating temperature and humidity in the workshop, the annual deformation is ≤0.02mm, resulting in a service life exceeding four years.

This Durable Heavy-Duty Copper Warp Stop Bar precisely meets the needs of projectile looms. Its unique design allows for seamless integration with the projectile loom's warp stop frame, requiring no adjustment during installation, improving fit efficiency by 25%. Its high elasticity and low deformation ensure stable operation at high projectile speeds, reducing downtime and maintenance.

Its corrosion resistance and low-friction surface ensure stable performance over long-term projectile production, making it particularly suitable for high-quality textile production, providing projectile loom users with a reliable warp breakage detection solution.